LONDON, April 11 (Xinhua) -- Humans will be further liberated from strenuous and monotonous labor thanks to the development of robotics, artificial intelligence (AI), big data and other technologies that lead to the fourth industrial revolution.

Industry and technology leaders have realized it is high time that businesses and universities prepare workers for the future in an innovative way.

FAREWELL TO STRENUOUS, REPETITIVE WORK

The Industry 4.0 Summit and Expo, the UK's largest event for the fourth industrial revolution, running from Wednesday to Thursday in Manchester, attracted start-ups, manufacturing companies, universities and other institutions that are involved in development and application of cutting-edge technologies.

Robots grabbing and placing items in order continue to be a selling point at the Expo but experts say robots can do more, for example, quality control to further relieve humans from time and labor intensive work which even risks human errors.

"Quality control ultimately needs to be automated. A robot and a camera saves 90 percent of labor time with improved accuracy. An AI-based approach that utilizes machine learning algorithms may discover when machines need to be fine-tuned to improve product quality," said Petr Bour with Alook Analytics, a consultancy that provides customized AI solutions.

Snap-on, an American tool and equipment manufacturer, exhibited its automated tool control system that is already used in aviation industry in the UK. Swiping a worker's pass to open and lock the tool storage and get the tools needed, the computer screen will immediately show who get what and when, requiring fewer people to take care of tools.

With a pair of smart glasses designed by AMA Xperteye, a remote engineering solution will be made more convenient as the engineer behind the computer can see exactly the same with the glasses wearer. "That means engineers don't have to travel around the world but solutions are more efficient," said Etienne Guillemot, Managing Director of the company.

MORE HUMANE TECHNOLOGY

Technologies are not only developed to make people's work easier, but also to make people's life more comfortable. Zhang Jia, a student of University of Manchester, designed a prosthetic hand with an innovative feature of voice recognition. Sonus, as they name it, allows the user to control their prosthetic hand by simply speaking to perform leisure, work and daily activities.

"It's more user-friendly, and doesn't require support of a healthy hand like other prosthetic hands do. Even disabled people who lost two hands can use it without problems," said Zhang.

The UK company HP1 Technologies developed a helmet with a sensor array embedded in, which can measure the size and location of the impact should a rider fall and strike the head. Alan Mcclelland with the Center for Process Innovation, which works with HP1 Technologies, expect the product will see a big market in U.S. in American football as head injury in sport has become a big issue nowadays.

3D printing experts are predicting more use of the technology in surgical planning, and leading 3D printing firms in the UK are innovating to lower barriers like the time-consuming and expensive process in traditional 3D printing for surgery.

PREPARE PEOPLE FOR THE FUTURE

There has been a lot of debate about whether automation will make people lose their jobs. But experts at the event seem are optimistic, believing that automation means new opportunities for future employment.

The University of Manchester has planned to deliver skills to support new, highly-paid employees and business leaders who work across all disciplines, including engineering, health and social sciences, to deliver applied research and expertise to support Industry 4.0 technologies and applications.

Festo, an automation company, showcased its "learning factory", an idea for education and training people for future. The company has developed modules that can be customized to enable university students or technical staff to have some hands-on learning.

"A lot of them are sent to universities and technical staff. It's cheaper than building a real factory. It gives people a lot more control of software and upskills people," said Andy Parker-Bates, Product Marketing Manager of Festo.

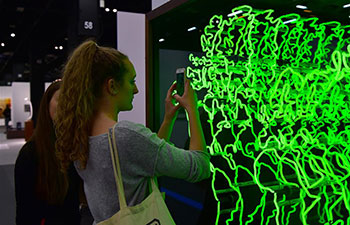

As 3D printing looks promising, the Manchester Metropolitan University has pioneered to build PrintCity, a advanced 3D printing hub for research and launched a master's degree program in industrial digitization for the first time in 2018 with 3D printing being a key word.

The program attracts students from a wide range of education background from fashion, medical science to animation, engineering and others, according to Gary Buller, technical officer of PrintCity.